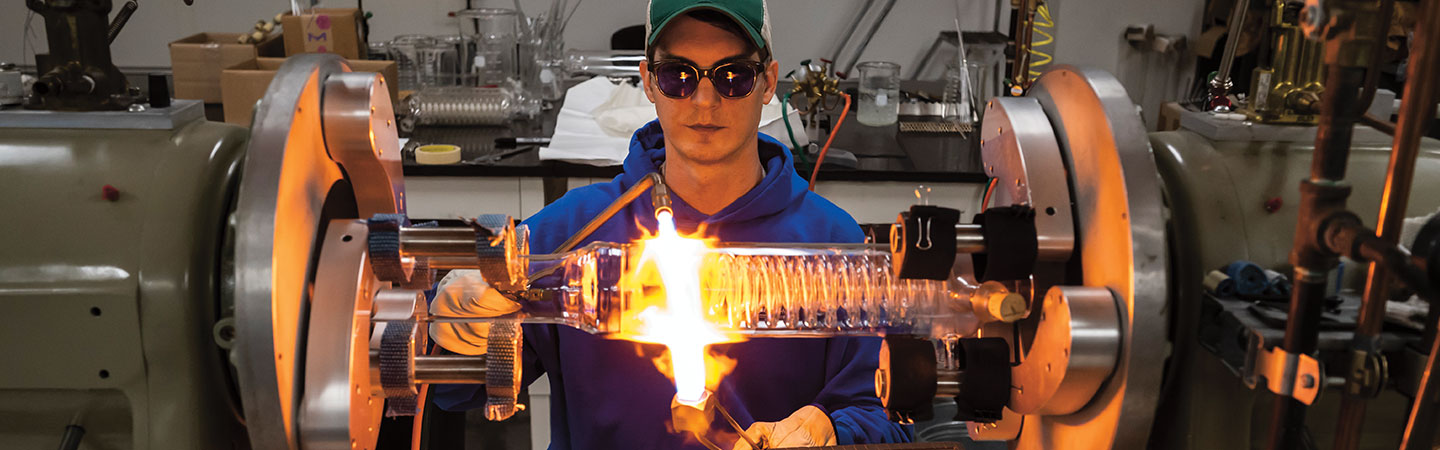

Think about the scientific equipment you might find in a lab. A surprising amount, like test tubes, beakers, and flasks, is made of glass. Some common glassware, like petri dishes used to grow bacteria and graduated cylinders for measuring the volume of liquids, can be purchased ready-made. But sometimes an experiment calls for a specialized piece of equipment. That’s when researchers turn to scientific glassblowers like Ryan Tate.

Tate works in the glass shop at the University of Pittsburgh in Pennsylvania. There, he repairs, modifies, and creates custom glassware for the school’s science departments. He does this by shaping molten glass into designs that are often complex, sometimes requiring him to fuse together dozens of small parts. Each piece is one of a kind. Recently, he spoke with Science World about how creating unique glassware helps make scientific breakthroughs possible.